info@topmarineeng.com

|

水下多功能作业机器入 / Underwater Multi-functional Detection ROV

产品简介

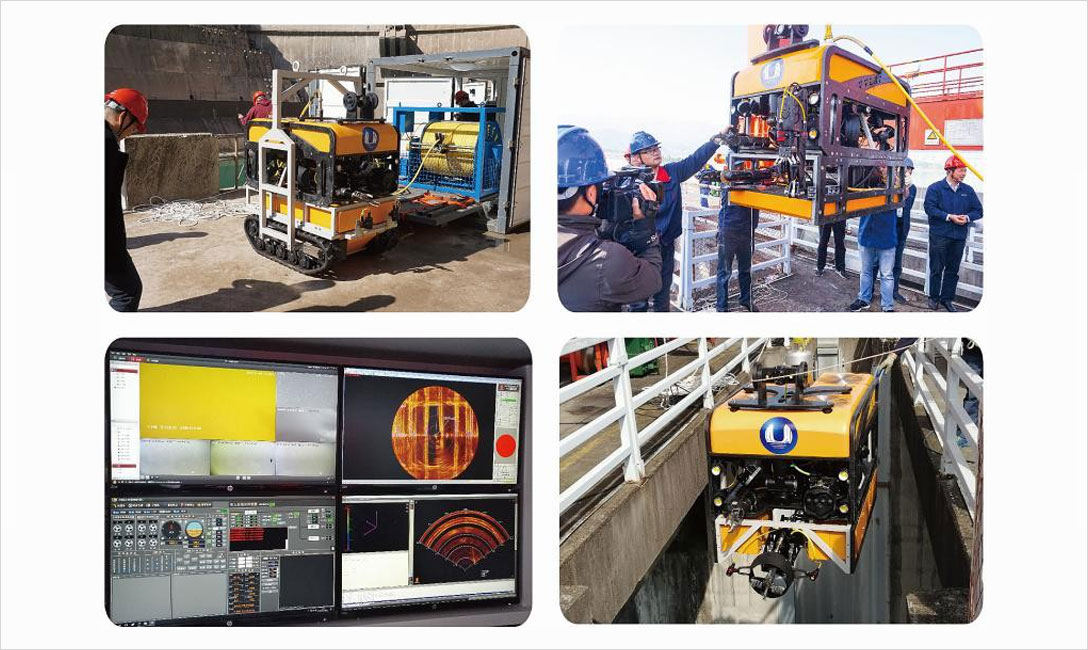

设计概述 Introduction 水下多功能作业机器入从目前流域梯级电站检修需求出发,开发制造的一款可出入水电站库区、尾水、流道、涵洞等多种环境的水电站水下检修专用有缆型机器人。主机单元携带了水下摄像、导航声呐、侧扫声呐、超短基线定位等多功能性搭载件,可实现水下定位、自视检查、声波检查等。整套系统采用多个加装层组合的独创方式,分别设置机械臂层、清洗打磨层、子机层、履带层,根据实际需要主机单元可分别与加装层单层或两层的组合使用,拆装方便。可集成实现摄像、声呐扫描、打捞、清障、清洗、打磨、剪切、管道检查等多种功能,实用的水下检修功能可在一定程度上代替潜水员,保障入身安全,提高工作效率。 Based on the current maintenance requirements of cascade hydropower stations in the basin, the underwater multi-functional operation machine is developed and manufactured as a special cable type robot for underwater maintenance of hydropower stations, which can enter and leave the reservoir area, tail water, flow channel, culvert and other environments. The main unit carries the multi-functional carrying parts such as underwater camera, navigation sonar, side scan sonar and ultra short baseline positioning, which can realize underwater positioning, self-examination and acoustic inspection. The whole system adopts the original way of combination of multiple adding layers, including the mechanical arm layer, cleaning and grinding layer, sub machine layer and track layer. According to the actual needs, the main unit can be used with single or two layers of adding layer respectively, which is convenient for disassembly and assembly. It can integrate camera, sonar scanning, salvaging, obstacle clearing, cleaning, polishing, shearing, pipeline inspection and other functions. Practical underwater maintenance functions can replace divers to a certain extent to ensure personal safety and improve work efficiency.

突破短板 Advantage

应用领域 Application 水下勘察水下打捞、水下作业,水下切割,水下探测,大坝检测,水电站紧窄区域勘察、水 下设备打磨等领域。 Underwater exploration underwater salvage, underwater operation, underwater cutting, underwater detection, dam detection, survey of tight area of hydropower station, underwater equipment grinding and other fields. 应用场景 Application scenario 三峡、洛溪渡水电站水下检修工程 Underwater maintenance project of Three Gorges and luoxidu hydropower stations

产品参数

技术参数 整备质量:1300mm*900mm*650mm 350kg 驱动系统:8 个无刷推进器,4 个水平推进器,4 个垂直升降推进器; 观测系统:前 200 万高清网络相机,最低照度 0.001lux, 声呐、图像同步扫描,双轴云台转角式±60° ; 照明系统:前端 4*50W LED 灯,左、右,后端各—个 15W 灯 ; 缆控系统:500m 中性零浮力承重电缆,采用电动缆车, 甲板单元:17 处理器,硬盘容量 1T;视频叠加功能; 作业能力:深度等级 300m, 航行速度水 3 节,下潜 2 节; 传感系统:三维电子罗盘,深度传感器、温度传感器, 机械手:开口最大长度为 180mm; 开角为 90°; 最大抓取重量为 15kg, 机械手轴向 360°重复旋转 履带车加装层: 行进速度 0-20m/min;通过搭载履带单元实现水底行走, 可实现对泄能区地面进行观察; 子母机加装层: 尺寸 230x400mm, 自重为 6Kg,水中零重力, 推力为 1Kg 搭载子母机单元, 释放子机进入坑洞进行观察 ; 机械臂加装层: 前端可用卡爪式、 钳式、 剪切器互换, 举升力 16Kg,夹取力 78Kg,破断力100Kg, 液压剪直径 30mm 软绳 清洗打磨加装层打磨机构绕轴 45°旋转, 打磨头可做 100mm 伸缩, 打磨头部位与打磨旋转轴为柔性连接, 自动补偿。 Technical parameter Size& weight: 1300mm * 900mm * 650mm 350kg Drive system: 8 brushless thrusters, 4 horizontal thrusters, 4 vertical lifting thrusters; Observation system: the first 2 million HD network cameras, with a minimum illuminance of 0.001lux, sonar and image synchronous scanning, double axis pan tilt angle ± 60 °; Lighting system: front 4 * 50W LED light, left, right, rear 15W light respectively; Cable control system: 500M neutral zero buoyancy load-bearing cable, with electric cable winch, Deck unit: 17 processor, hard disk capacity 1T; video&text overlay function; Operation capacity: Depth 300m, navigation speed 3 knots, submergence 2 knots; Sensing system: three dimensional electronic compass, depth sensor, temperature sensor Manipulator: the maximum opening length is 180mm; the opening angle is 90°; the maximum grabbing weight is 15kg, and the manipulator rotates 360°repeatedly in axial direction Adding layer of crawler: Traveling speed is 0-20 M/min; underwater traveling can be realized by carrying crawler unit to observe the ground in energy discharge area; The additional layer of the sub master machine: the size is 230x400mm, the self weight is 6kg, the water has zero gravity, the thrust is 1kg to carry the sub master machine unit, release the sub machine into the pit for observation; Additional layer of mechanical arm: The front end can be interchanged with claw type, clamp type and shear type, with lifting force of 16KG, clamping force of 78kg, breaking force of 100kg, and hydraulic shear diameter of 30mm soft rope The grinding mechanism of cleaning and grinding additional layer rotates 45°around the shaft, the grinding head can be expanded by 100mm, and the grinding head part and the grinding rotating shaft are flexibly connected with automatic compensation. |